The Issue

The Turbine Diaphragm is an assembly that required repetitive modelling and drawing changes, which was very time consuming. In addition to this problem, valuable time was spent in QC of the remodeled Diaphragm. Due to the time constraints, heavy workload and consistent projects incoming, the workforce was getting bigger and the revenue smaller.

Proposed Solution

By accessing the Solidworks API and using external Programming tools, these repetitive tasks could be effectively automated, thereby reducing the workforce or using their effort elsewhere.

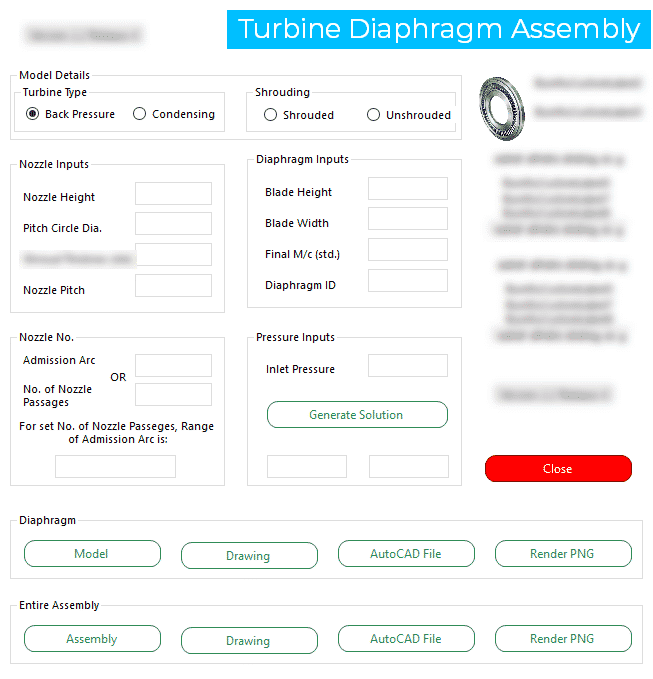

A UI was proposed, to know the extent of customization being developed. Large Data and calculations were gathered as the input and the models would be created for the sole purpose of being customized.

With this Solution, there would be a drastic decrease in the number of Design Engineers for modelling and QC. Their time can be better utilized in R&D.

Parameters and Features

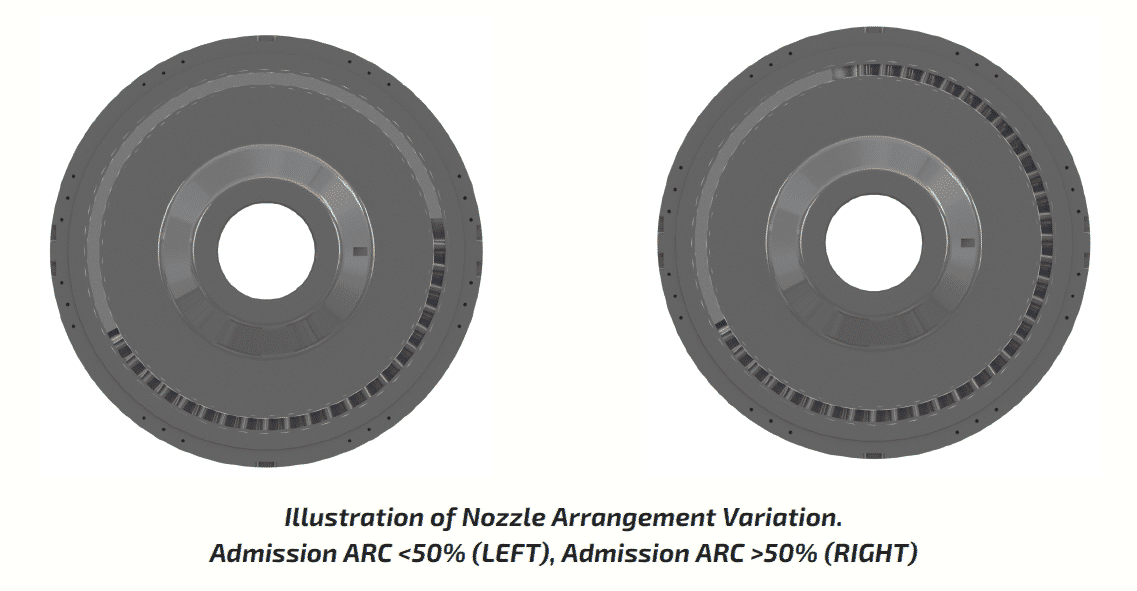

The input data such as drawing files, standard tables and Design Calculations were given. All these input data were converted into code to provide an automated output, below are the parameters and features that were customized based on the client's requirement.